The energy-saving pressure screens generally adopt an upflow structure design. The pulp enters the pressure screen from the bottom and generates centrifugal force and pressure difference under the action of the high-speed rotation of the rotor.

Call Us

(+86) 371-55129198

Email Us

leizhanmachinechina@gmail.com

Global Certificate

ISO 9001:2023

The energy-saving pressure screens generally adopt an upflow structure design. The pulp enters the pressure screen from the bottom and generates centrifugal force and pressure difference under the action of the high-speed rotation of the rotor.

The reeling machine is a key equipment for winding and forming paper produced by the paper machine, which directly affects the production efficiency and the convenience of subsequent processing.

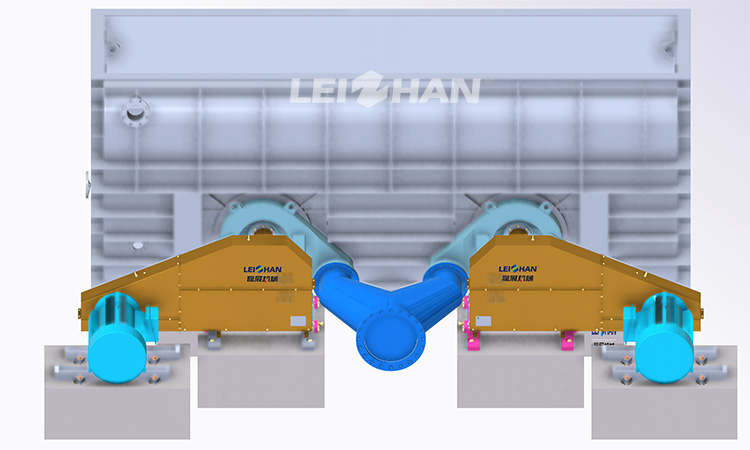

The broken pulper has a strong processing capacity. Its solid body and powerful pulping system can easily and quickly break down various types and thicknesses of paper into fibrous pulp.

As one of the spare parts of the paper machine, the sizing machine affects the paper making process. The sizing machine can enhance the physical properties of paper and improve the grade of paper by applying sizing to paper.

The high-grade paper mill flotation deinking machine provided by Leizhan company uses the principle of bubble flotation to effectively remove ink and adhesives from the pulp to obtain high-quality pulp.

The heating screw conveyor adopts an advanced structural design to ensure efficient production capacity and stable operation. The heating screw conveyor can meet the strict requirements of the pulp and paper industry.